Pigment blue 15:0-Corimax Blue 6850P

Technical parameters of Pigment blue 15:0

| Color Index No. | Pigment blue 15:0 |

| Product name | Corimax Blue 6850P |

| Product category | Organic Pigment |

| Light Fastness(coating) | 7 |

| Heat Resistance(coating) | 180 |

| Light Fastness(plastic) | 7-8 |

| Heat Resistance(plastic) | 220 |

Color |  |

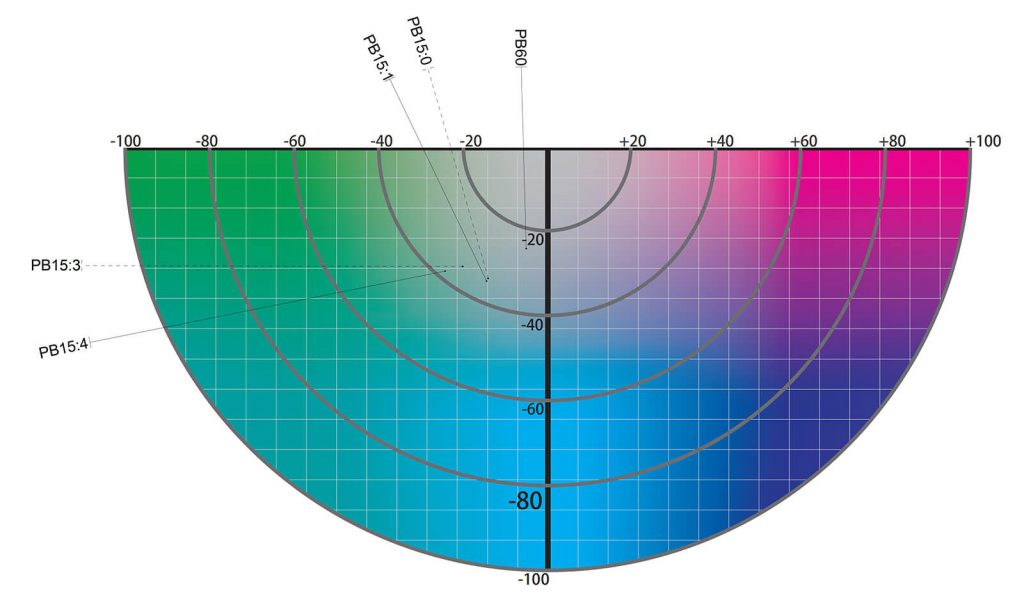

| Hue distribution |

Features: good dispersion, high color strength.

Application:

Recommended for architectural coatings, industrial paints, powder coatings, printing pastes, PVC, rubber, PS, PP, PE, offset inks, water-based inks.

Can be applied to PS, UV ink.

Detailed Characteristics:

Chemical Structure:

Pigment Blue 15:0 is a copper(II) complex with the phthalocyanine ligand.

It forms a planar macrocyclic structure with extensive conjugation, contributing to its deep blue color.

Physical Properties:

Molecular Weight: 576.08 g/mol

Density: Approximately 1.6 g/cm³

Melting Point: It sublimates without melting under normal atmospheric conditions.

Solubility: Insoluble in water and most organic solvents, which enhances its stability in various applications.

Synthesis:

Method: Typically synthesized by cyclotetramerization of phthalonitrile in the presence of a copper salt (e.g., copper(I) chloride) under high-temperature conditions. This reaction forms the phthalocyanine ring structure with copper at the core.

Properties:

Lightfastness: Exceptional lightfastness, making it highly resistant to fading under prolonged exposure to light.

Chemical Stability: Resistant to acids, alkalis, and organic solvents, ensuring durability in harsh environments.

Heat Stability: Can withstand high temperatures without significant degradation, suitable for various high-temperature applications.

Color Characteristics: Deep, intense blue color with high tinting strength, providing vivid coloration even at low concentrations.

Applications:

1.Paints and Coatings:

Used in automotive, industrial, and architectural coatings for its brilliant color and durability.

Also employed in artist paints, offering vibrant hues and longevity.

2.Plastics:

Utilized in the production of colored plastics, such as polyethylene, polypropylene, and polystyrene.

Its high stability ensures that the color remains consistent during plastic processing.

3.Inks:

Widely used in printing inks for packaging, textiles, and publications due to its bright color and resistance to bleeding.

4.Textiles:

Applied in textile printing and dyeing processes to achieve vibrant and long-lasting blue shades.

Used in both synthetic and natural fibers.

5.Rubber and Elastomers:

Incorporated into rubber products to impart color without affecting the material's properties.

Variants:

Pigment Blue 15:1: Beta form, known for improved dispersion and slightly greener shade.

Pigment Blue 15:2 to 15:6: Various crystalline modifications offering different hues, dispersion characteristics, and specific application advantages.

Safety and Handling:

Toxicity: Generally considered non-toxic; however, inhalation of dust should be avoided.

Safety Measures: Use personal protective equipment (PPE) such as gloves, masks, and goggles to prevent inhalation and skin contact during handling.

Environmental Impact: It is relatively inert and does not pose significant environmental hazards; however, standard environmental safety practices should be followed to prevent accidental release.

Environmental and Regulatory Aspects:

Regulations: Complies with various international safety standards for use in consumer products.

Environmental Impact: Considered environmentally benign due to its insolubility and stability, which minimizes its potential for bioaccumulation.

Pigment Blue 15:0's excellent stability, vibrant color, and wide range of applications make it a valuable pigment in many industries, serving as a base for more specialized variants and products.