Pigment yellow 183-Corimax Yellow RP

Technical parameters of Pigment yellow 183

| Color Index No. | Pigment yellow 183 |

| Product name | Corimax Yellow RP |

| Product category | Organic Pigment |

| Light Fastness(coating) | 6 |

| Heat Resistance(coating) | 180 |

| Light Fastness(plastic) | 7 |

| Light Fastness(plastic) | 280 |

Color |  |

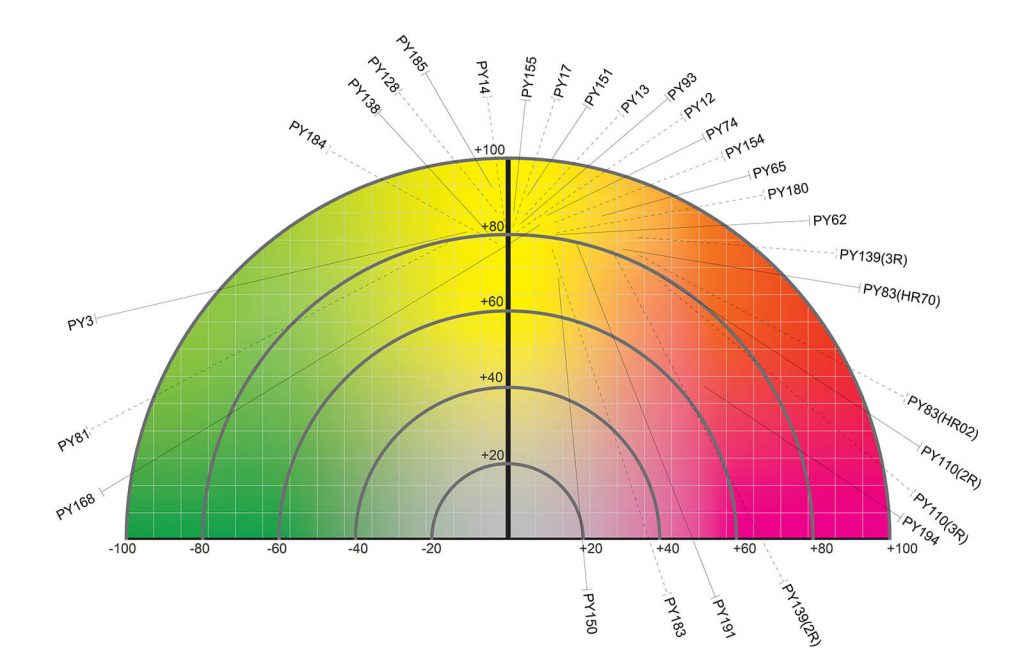

| Hue distribution |

Features: good migration resistance.

Application:

Recommended for powder coatings, PVC, rubber, PS, PP, PE, offset ink, water based ink, solvent ink, UV ink.

Can be applied to PU.

Related Information

Color Index:PY 183

Chem. Group: Monoazo

C.I. No. :18792

Cas. NO:65212-77-3

Physical Data

| Density [g/cm³] | 1.70-1.90 |

| Specific Surface [m²/g] | - |

| Heat Stability [°C] | 280①/180③ |

| Light fastness | 6②/7④ |

| Weather fastness | 5 |

① Heat fastness in plastic

② Light fastness in coating,ink

③ Heat fastness in coating,ink

④ Light fastness in plastic

Fastness properties

| Water resistance | 4 |

| Oil resistance | 4 |

| Acid resistance | 5 |

| Alkali resistance | 5 |

| Alcohol resistance | 4-5 |

Pigment yellow 183 has excellent heat stability. In the process of coloring high-density polyethylene (HDPE) with 1/3 standard depth, its thermal stability can reach 300 ° C, and it does not cause dimensional deformation. , Suitable for coloring of plastics (such as engineering plastics ABS, HDPE, etc.) that require processing at higher temperatures.

aliases:18792; C.I. Pigment Yellow 183; Calcium 4,5-dichloro-2-((4,5-dihydro-3-methyl-5-oxo-1-(3-sulphonatophenyl)-1H-pyrazol-4-yl)azo)benzenesulphonate; calcium 4,5-dichloro-2-{(E)-[3-methyl-5-oxo-1-(3-sulfonatophenyl)-4,5-dihydro-1H-pyrazol-4-yl]diazenyl}benzenesulfonate.

Molecular Structure:

Physical and chemical properties:

Solubility: Hue or shade: Red light Yellow Relative density: Bulk density / (lb / gal): Melting point / ℃: Average particle size / μm: Particle shape: Specific surface area / (m2 / g): pH / (10% Size): oil absorption / (g / 100g): hiding power:

Product Usage:

In recent years, red-yellow-yellow lake-based pigments that have been put on the market for plastics have excellent heat resistance and stability despite their slightly lower tinting power. In the high-density polyethylene (HDPE) coloring process of 1/3 standard depth, Stability can reach 300 ° C, and there is no dimensional deformation, and light fastness is 7-8 grades. It is suitable for coloring of plastics (such as engineering plastics ABS, HDPE, etc.) that require processing at higher temperatures.

Synthesis principle:

From the diazo component 2-amino-4,5-dichlorobenzenesulfonic acid, an aqueous solution of yellow nitrite was added according to a conventional method to carry out a diazotization reaction, and excess nitrous acid was removed with ammoniasulfonic acid; 3'-sulfonic acid phenyl) -3-methyl-5-pyrazolinone, which is coupled in a weakly acidic medium (pH = 5-6), and then reacts with calcium chloride to transform into a calcium salt lake, Heat, filter, wash and dry.