Pigment blue 15:4-Corimax Blue GLVO

Technical parameters of Pigment blue 15:4

| Color Index No. | Pigment blue 15:4 |

| Product name | Corimax Blue GLVO |

| Product category | Organic Pigment |

| Light Fastness(coating) | 7 |

| Heat Resistance(coating) | 200 |

| Light Fastness(plastic) | 7-8 |

| Heat Resistance(plastic) | 250 |

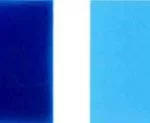

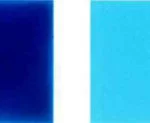

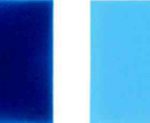

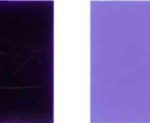

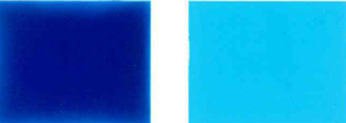

Color |  |

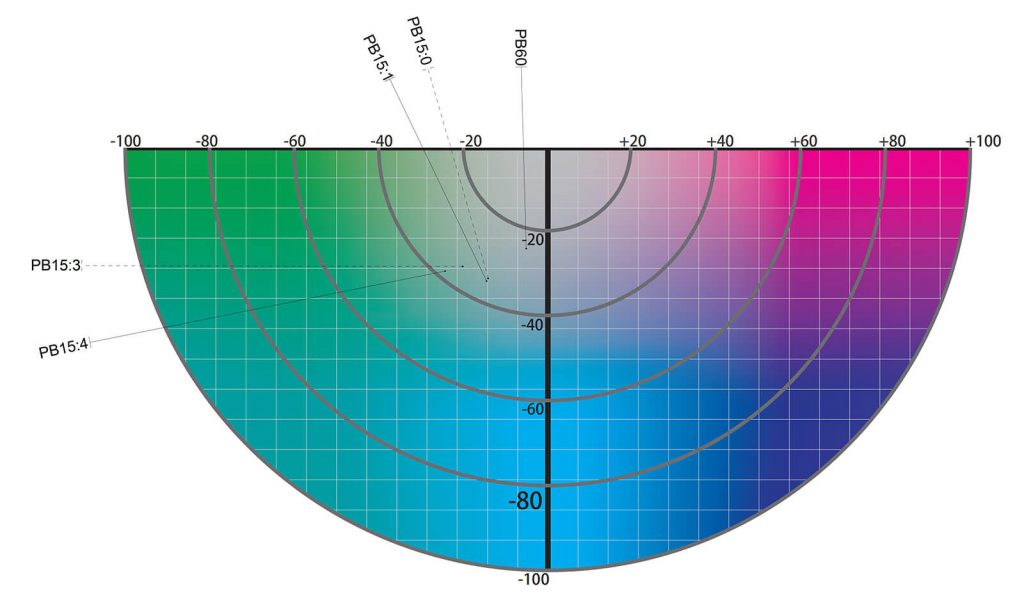

| Hue distribution |

Features: low viscosity, high color strength, high gloss.

Application:

Recommended for automotive paints, architectural paints, industrial paints, water based inks, solvent inks, UV inks.

Pigment Blue 15:4 is a variant of the copper phthalocyanine family, which is specifically designed for certain applications where enhanced properties are required. It shares the fundamental structure of Pigment Blue 15:0 but exhibits unique characteristics due to its specific crystalline form. Here are detailed insights into Pigment Blue 15:4:

Detailed Characteristics:

- Chemical Structure:

- Similar to Pigment Blue 15:0, it is a copper(II) phthalocyanine complex.

- It features a specific crystal modification that differentiates it from other variants.

- Physical Properties:

- Molecular Weight: 576.08 g/mol (same as other phthalocyanine blues)

- Density: Varies slightly from other forms due to different crystalline structure.

- Solubility: Insoluble in water and most organic solvents.

Properties:

- Lightfastness: Excellent, similar to other phthalocyanine pigments, making it highly resistant to fading.

- Chemical Stability: Very resistant to acids, alkalis, and organic solvents.

- Heat Stability: Can withstand high temperatures without significant degradation.

- Color Characteristics: Exhibits a slightly different hue and dispersion characteristics compared to other forms like 15:0 and 15:1. It often shows a greener shade of blue and improved rheological properties.

Applications:

- Paints and Coatings:

- Used in high-performance industrial coatings where specific rheological properties are required.

- Suitable for automotive coatings due to its stable and vibrant color.

- Plastics:

- Applied in coloring plastics where enhanced dispersion and stability are necessary.

- Often used in high-quality consumer goods.

- Inks:

- Utilized in printing inks that require precise color matching and stability.

- Preferred in applications where color consistency and performance are critical.

- Textiles:

- Used in high-end textile applications where specific color properties and fastness are needed.

- Specialty Applications:

- Employed in applications requiring precise color performance and stability under harsh conditions.

Safety and Handling:

- Toxicity: Generally considered non-toxic. However, standard precautions should be taken to avoid inhalation or prolonged skin contact.

- Safety Measures: Use appropriate PPE such as gloves, masks, and goggles when handling the pigment.

- Environmental Impact: Environmentally stable, but standard safety practices should be followed to prevent accidental release.

Environmental and Regulatory Aspects:

- Regulations: Complies with international safety standards for use in consumer and industrial products.

- Environmental Impact: Stable and non-reactive, minimizing environmental hazards.

Pigment Blue 15:4 is designed to meet specific needs in industries requiring high-performance pigments. Its unique crystalline form provides distinct advantages in terms of color stability, dispersion, and application properties.