Pigment Red 166-Corimax Red RN

Product parameter list

| Color Index No. | Pigment Red 166 |

| Product name | Corimax Red RN |

| Product category | Organic Pigment |

| Light Fastness(coating) | 7 |

| Heat Resistance(coating) | 180 |

| Light Fastness(plastic) | 7-8 |

| Heat Resistance(plastic) | 280 |

Color |  |

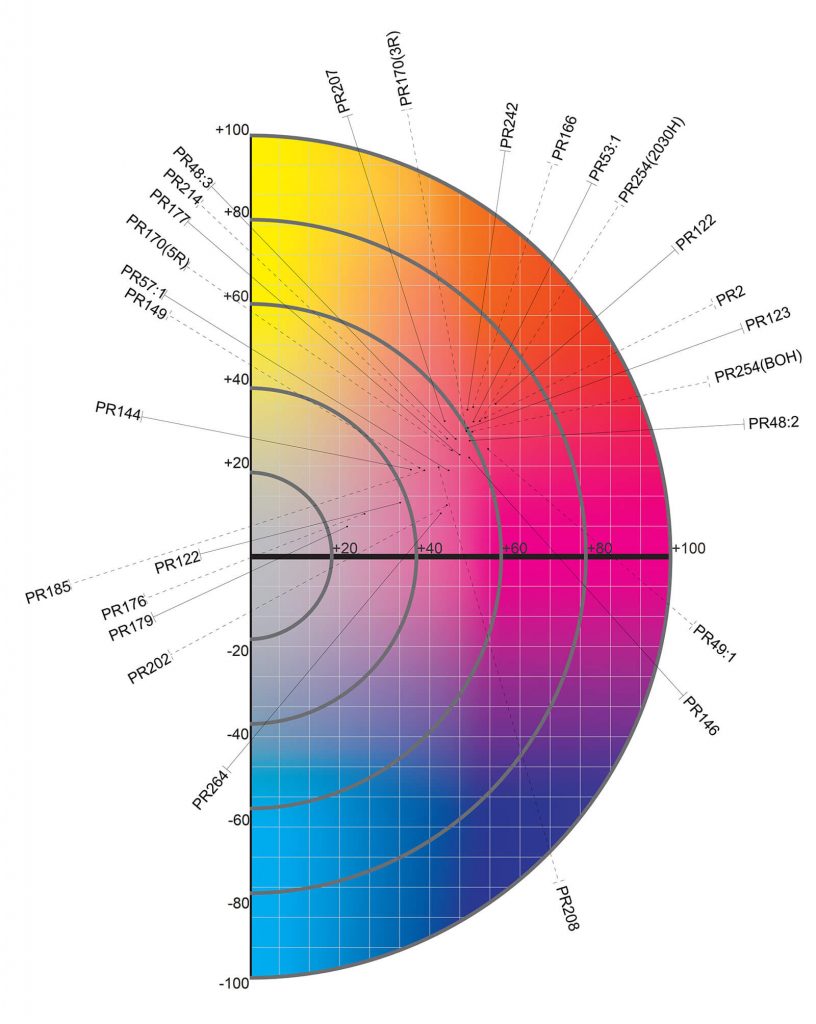

| Hue distribution |

Application:

Recommended for automotive paints, architectural paints, industrial paints, powder coatings, printing pastes, PVC, rubber, PS, PP, PE, PU, water based inks, solvent inks, UV inks.

Suggested for coil coatings, offset inks.

Other red pigments: Pigment Red 170, Pigment Red 122, Pigment Red 254. These products are also the main products of Zeya, with high sales and good quality. If you are interested in these products, you can visit the product page for details.

Related Information

English name: Cromophtal Scarlet R (CGY)

English alias: CIPigment Red 166; PR166; Disazo Scarlet; Cromophtal Scarlet R; 2-Naphthalenecarboxamide, N, N'-1,4-phenylenebis [4-[(2,5-dichlorophenyl) azo] -3-hydroxy- ; Pigment Red 166; CI 20730

CAS number: 3905-19-9; 71819-52-8

EINECS number: 223-460-6

Molecular formula: C40H24Cl4N6O4

Molecular weight: 794.4684

InChI: InChI = 1 / C40H24Cl4N6O4 / c41-23-9-15-31 (43) 33 (19-23) 47-49-35-27-7-3-1-5-21 (27) 17-29 ( 37 (35) 51) 39 (53) 45-25-11-13-26 (14-12-25) 46-40 (54) 30-18-22-6-2-4-8-28 (22) 36 (38 (30) 52) 50-48-34-20-24 (42) 10-16-32 (34) 44 / h1-20,51-52H, (H, 45,53) (H, 46, 54)

Molecular Structure:

Physical and chemical properties:

Hue or light: yellow light red

Relative density: 1.57

Bulk density / (lb / gal): 13.08

Melting point / ℃: 340

Particle shape: needle

Specific surface area / (m2 / g): 26

pH value / (10% slurry): 7

Oil absorption / (g / 100g): 55

Covering power: translucent

Product Usage:

Pigment Red 166 has a pure yellow light red color. It is mainly used for coloring plastics and printing inks. It is resistant to migration in soft PVC, has medium coloring strength, hiding power, good light resistance and weather fastness; it can be heat-resistant in HDPE To 300 ° C, the transparent type has a light resistance of level 8. It is also used for coloring polyacrylonitrile, polystyrene, and rubber. It is also recommended for high-end industrial automotive coatings, packaging printing inks and metal decorative printing inks.